Production Processes and Equipment

Semi-automated and full-automated production processes

PCB assembly line

In 2012 we purchased a new High-Speed Flexible Mounter Pick and Place machine KE1080 series from Juki combined with a reflow VITRONIC. We also added another Juki High-Speed Flexible Mounter and reflow in 2018.

This provides the necessary flexibility for a big variety of the PCBA's we need to assemble for our customers.

Low pressure molding machines

At Advanced ID Asia, we currently have more than a dozen high precision low-pressure molding machines in operation. Productivity and safety are of the highest standard and proofed by many applications in the automotive and industrial industry. Due to the low-pressure technology even most advanced PCBA’s can be safely enclosed and are protected against water and dust. One of our currently used materials Macromelt® withstands temperatures from -40C° to 130C°. These machines are fully designed and built at Advanced ID Asia

**(click here to download brochure)**

High precision wire stripping

Almost all production lines are equipped with semi-automatic programmable stripping machines designed to perform both single and multiple stage strips. This enables an automotive confirm production according to IPC standards each cable strip combination is validated under a microscope and after crimp is applied an destructible pull-force test is performed to guarantee a well executed crimp/wire connection.

Metal processing

We process different types of materials, among these, are copper, brass, aluminium, metal, stainless steel, PP, POM, silicone, rubber and many more. Our in-house workshop produces jigs and testing equipment but it is also equipped with semi and fully-automated mass production machines to suit OEM required parts and keeps our production afloat. Our processes are IATF 16949 and ISO 9001 certified as well.

Conformal coating

Potting

Potting is a process of filling a complete electronic assembly with a solid or gelatinous compound for resistance to shock and vibration, and for exclusion of moisture and corrosive agents. Among other benefits it can also be seen as a design-protection against copycats. Thermosetting plastics or silicone rubber gels are often used, though epoxy resins are also very common

Plastic injection molding

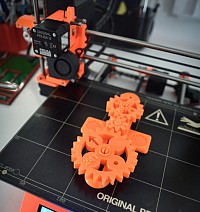

3D printing technologies

3D Optical Measurements

This device is a must for incoming inspection and quality control of silicone, plastic injection and metal parts. The non-contact optical

photoelectric

measurement system operates with high precision no force is applied which has great benefit to measure soft materials such as rubber or silicone. It is possible to validate roundness, centricity and other symmetrical requirements without damaging the part.